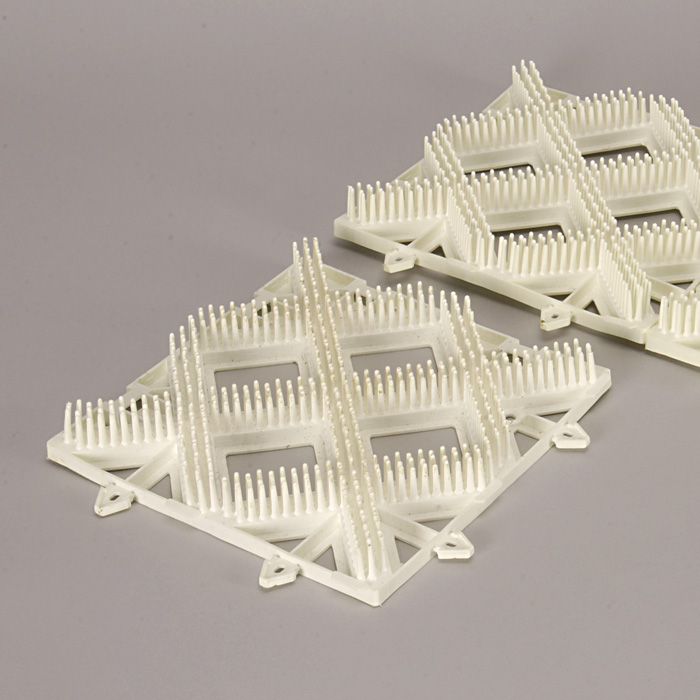

Skitrax Tiles

These come from New Zealand, so there is a 4-6 week lead time.

Save maintenance dollars on lift loading/unloading and corral areas. Use on entrance ramps to ski patrol and maintenance buildings.

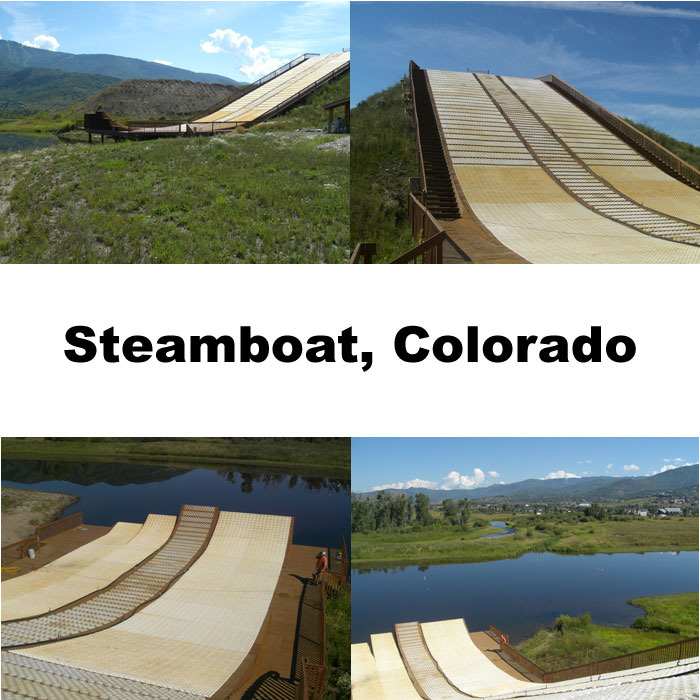

Ideal for freestyle and summer skiing facilities

Excellent for lift exit and entrance ramps

RRS exclusive in the USA

Injection molded

UV Stabilized

Interlocking 8.78" x 8.78" tiles

8.12oz per tile Rated to -121°F

25.5lbs (11.5kg) per carton

Please call for availability

How many tiles do I need?

Each tile is approximately .535 ft2, so take your square footage, and multiply it by 1.869. That should give you a rough idea how many tiles you need.

Minimum order is 1 carton (48 tiles).

Product Description | Interlocking units, injection-moulded and formulated to produce a rugged low friction ski surface. |

Applications | Many applications exist, including: Synthetic ski slopes Freestyle jump ramps Ski lift loading terminals, unloading ramps, queue lines Ski jumps High traffic zones (snow field access points, bottlenecks, near car parks & buildings) |

Dimensions | Gross measure of 245 x 243 x 35 mm per tile (9.65 x 9.57x 1.38 inches) |

Coverage (net) | 225 x 225 mm / tile (8.86 x 8.86 inches) 1 tile = 0.051 m² (1 tile = 0.545 sq foot) 20 tiles / m² (1.835 tiles / sq foot) |

Weight | Net weight approx 230 grams per tile (8.12 oz or 0.507 lbs) |

Packaging | 48 tiles per carton, 0.480 x 0.265 x 0.500 = 0.064m³ / carton 18.9 x 10.5 x 19.7 inches / carton Gross weight 11.5 kg /carton 25.5 lbs/carton 21,504 tiles per 20' container in 448 cartons (estimate only) Shrink-wrapped pallets available for large quantities |

Base Material | EVA copolymer |

Brittleness Temperature | (F50)<-85°C (-121°F) (ASTM D746) |

Thermal Expansion | 2 x 10-4/°K, which is approximately 0.02%/°C eg: from 0° to 30°C one tile will expand 1.35 mm (32 to 86°F 0.053 inches) |

Expansion System | Each tile allows 3 mm 0.12 inches expansion by design |

UV Stability/Colour | UV stability has been proven and tested by our own use of Skitrax over nine years in New Zealand which typically has the highest UV penetration in the world. Any colour can be manufactured, but white provides highest UV resistance. |

Quality Systems | All raw material suppliers certified to ISO 9001 Contract injection moulder certified to ISO 9001 Made in New Zealand |

Guarantee/Warranty | For full details refer to |

Measurements | Metric dimensions are accurate, US approximate |

Synthetic Slope Installation | |

Gradients | Beginner up to 1:7 (14.3 %) with counter slope run out Intermediate up to 1:6 (16.5 %) on average Advanced up to 1:5 (20.0 %) on average Moguls can be installed |

Design | Smoothly contoured, well-drained, sealed sub base capable of preventing water entry from sides and surface, geotextile usually laid before Skitrax ski tiles. |

Anchor | Fasten 5 mm 0.2 inches galvanized wire across top of slope anchored with pegs of suitable length and of a design suitable for the prevailing ground conditions every 450 mm 1.6 ft holding this wire firmly flush in sub-base, attach first row of interlocked ski tiles using UV stabilized cable ties (expansion joints to point to the same side and downwards of slopes at all times). For plywood ramp installation use all screw holes to secure the first row of Skitrax Ski Tiles and allow following rows to float, after not more then 5 meters (16 ft) repeat this process, narrower length strips allow more control of heat expansion spacing. |

Laying | Easily assembled interlocking units are clipped together to form large mat below anchor line (slope width x 5 meters 16 ft down), for the next five meters use same sequence again (anchor/laying). |

Labour | Approximately 150-200 hours per 1,000 m² (0.247 acres). |

Repair | Individual tiles can be easily replaced if required. |

Durability | Life and performance can be extended by using fine fog style water lubrication (see below). Rotation of Skitrax Ski Tiles (swapping high traffic tiles with low traffic tiles) enhances product life. |

Quality | Skitrax Ski Tiles are highly durable, are easily maintained and provide an excellent glide, allowing all year round skiing. |

Typical Ski Field Applications | In marginal snow conditions earth contact can be prevented, allowing skier traffic to access and use ski resort facilities and lifts. Skitrax Ski Tiles prevent snow being pushed away in critical areas. |

Surface | No pre-requisites if ground not too soft, soft surface should be stabilized with shingle, compaction techniques, or similar, drainage may help. |

Anchor | In low gradient area very little anchoring is required, in softer conditions use larger pegs. In steeper slope situations, professional anchoring and adequate underground stabilization close to ski slope installation is recommended. |

Cooling & Lubrication | |

Water Spray | To keep slope and ski surfaces cool and create improved glide and extended ski and slope life, finest mist foggers are placed about every 2 to 3 meters (6.5 to 10ft) along the bottom row of each tile matt section and along the edge of the slope using standard UV stable piping. |

Components | System normally comprises of pumps, header/storage tanks (ideally designed to collect rainwater), filtration, pressure control valves, control system (to water only those areas desired), piping network, fine mist foggers, a water recirculation option to conserve water. |